Acrylic sealant

Acrylic sealant

Key Features

Why Choose Acrylic sealant

- It has high elasticity and flexibility, and can resist ultraviolet rays, ozone and extreme climate aging for a long time

- It has excellent sealing protection performance

- It is resistant to salt fog, acidic and alkaline media and solvent erosion, protecting the metal substrate and having excellent bonding adaptability. Application scenario: Waterproof treatment for areas prone to shrinkage such as walls, floors, corner joints, etc.; bonding of glass and aluminum alloy frames; sealing of exterior wall joints, interior joint filling, sealing of pipe holes passing through walls, sealing of chimneys and ventilation openings, etc.

Quick Specs

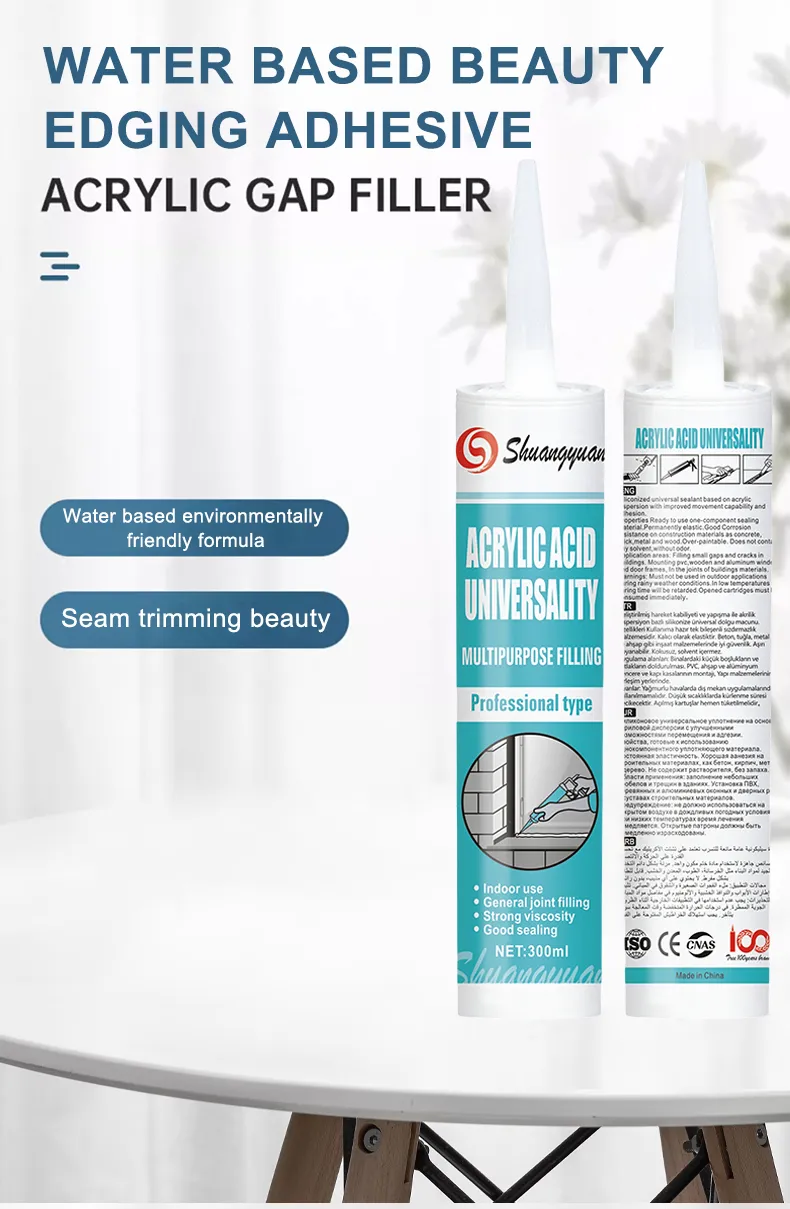

- Product name

- Acid cured silicone sealant

- Model No.

- Acrylic acid

- Main material

- Silicone sealant

- Color

- Transparent/White

- Packing

- 300ml/ PCS, 24 PCS/box

Specifications

Technical Parameters

| Parameter | Value |

|---|---|

| Product name | Acid cured silicone sealant |

| Model No. | Acrylic acid |

| Main material | Silicone sealant |

| Color | Transparent/White |

| Packing | 300ml/ PCS, 24 PCS/box |

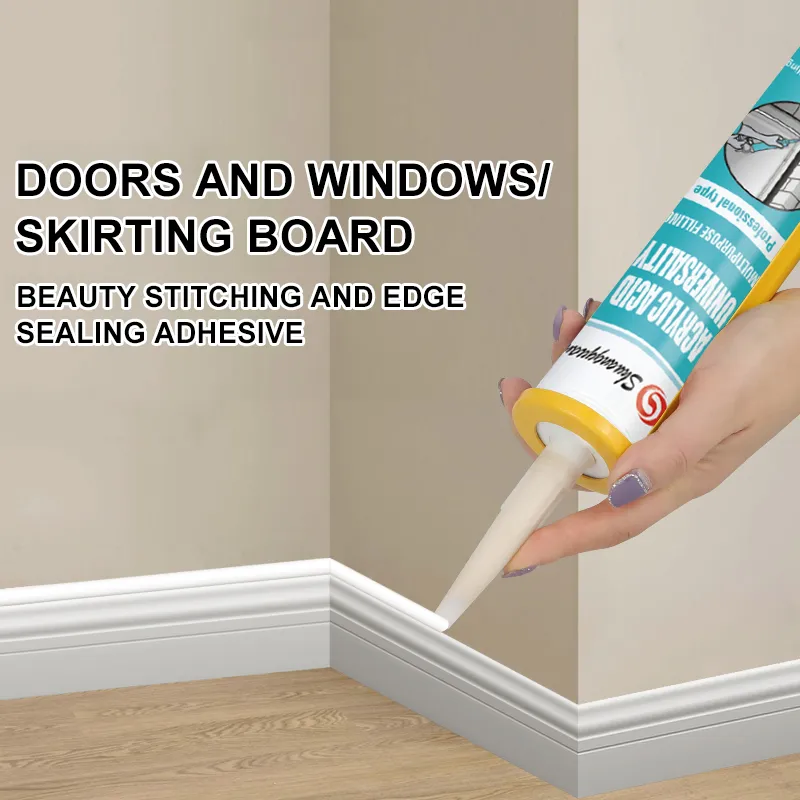

| Application | Wall surfaces, baseboards, and other interior joint sealing; sealing of pipe holes passing through walls; sealing of chimneys and ventilation openings. |

| Certification | ISO9001、CE、ROHS、MSDS |

| Shelf life | 12 months |

| Operating temperature | -5°C to 40°C |

| Surface curing time | 3-5 minutes |

Data Sheets

Specification Documents

Solutions

Related Solutions

Explore how Acrylic sealant fits into our comprehensive sealant solutions for construction and industrial applications.

Resources

Technical Articles

Guides and insights related to acrylic sealant applications.

Silicone sealant manufacturer note: structural sealant warranty terms are typically defined by the project contract/specs, while product warranty follows Shuangyuan’s 3-year policy and TDS (contact us for selection support such as SY-9900 where applicable).

Silicone sealant manufacturer note: weatherproof sealant focuses on joint sealing and exposure resistance, while structural sealant is for load-bearing bonding/structural glazing—select per project specs and the product TDS.

A simple way to distinguish bulging vs bubbling and assess whether the issue is more likely related to the sealant or the substrate, based on surface appearance and cross-section inspection.

Interested in Acrylic sealant?

Get custom quotes, samples, or technical support from our team.